The next installment in our Drafts: The Written Language of Weaving series digs deep into the instructions for how to actually execute the weaving process to create cloth.

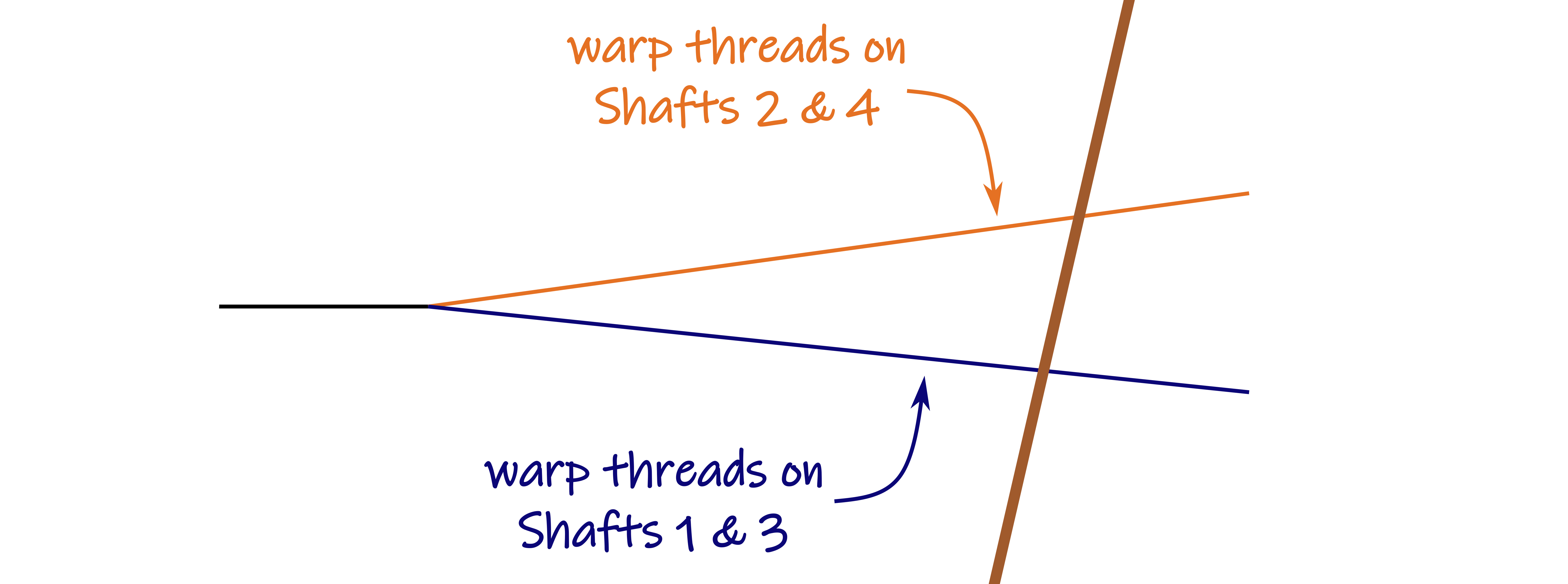

We’ll begin by talking about sheds. You’ll learn what they are, why they’re important, how looms create them. Then you’ll learn about different kinds of shed diagrams, what the shed diagram’s job is and what it tells you, which type is most suitable for your loom, and how to read them.

Once we’ve laid that foundation, we’ll look first at the type of shed diagram written for looms without tie-ups: the liftplan. This is the section of the course specifically for owners of table looms, directly tied floor looms, and dobby looms. You’ll learn why those looms need a special kind of shed diagram, how to read it, why it’s so rare to find a “sinkplan,” and how to make one if you want one!

We’ve also added a new toolbox for this course that teaches you how to convert a treadling + tie-up to a liftplan, so that you can use any draft successfully with your loom.

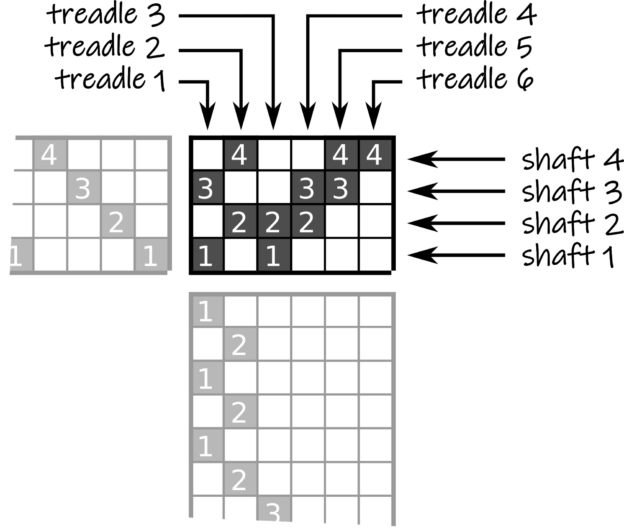

The next part of the course is for owners of jack looms, counterbalance looms, and countermarch looms. In it, we’ll look at the type of shed diagram written for floor looms with lamms: the treadling + tie-up and you’ll learn how they work together and why one is no good without the other.

In particular, we’ll talk about the thorny problem with tie-ups: figuring out their shed direction! You’ll learn how to tell whether a tie-up is written for your type of loom, what happens when the tie-up and your loom don’t match, how to fix it, and whether you even need to.

From there, we’ll look at different kinds of tie-ups. You’ll learn the difference between direct, universal, and multishaft tie-ups and the advantages of each. You’ll also learn what a skeleton tie-up is and when you might need one, plus an example of how to create one.

We’ll wrap up our look at tie-ups with countermarch tie-ups. Countermarch loom owners will learn how to read tie-ups written specifically for your loom and how to use tie-ups that aren’t. You’ll learn why the usual direct, universal, and skeleton tie-ups won’t work on your loom, but you’ll also learn some unusual ones that will!

Finally, we’ll get to the most familiar part of the shed diagram for shaft looms: the treadling. You’ll learn the basics of how to read a treadling and special notations that will only be found in treadlings and liftplans. Then you’ll learn how to rearrange a tie-up in order to make a treadling easier to follow and how to flip a tie-up over to make it easier to treadle in general.

We’ll wrap up with two lessons in which you’ll learn tricks for avoiding treadling mistakes while weaving and what those two little words “use tabby” mean.

The final course in the Drafts: The Language of Weaving series will be Drawdowns: Blueprints for Success.

Useful Toolboxes

- How to convert a treadling + tie-up to a liftplan

- How to convert a liftplan to a treadling + tie-up

- How to tell whether your loom has a rising or sinking shed

- How to tell whether your draft is for a rising or sinking shed

- How to convert from rising to sinking shed and vice versa

- Is plain weave possible on this threading?

Equipment needed

None

Weaving skills needed

None

Other courses in this series

- Drafts: the Written Language of Weaving

- The Threading: Where Every Draft Begins

- The Secrets of Liftplans, Treadlings, and Tie-ups

- Drawdowns: Blueprints for Success